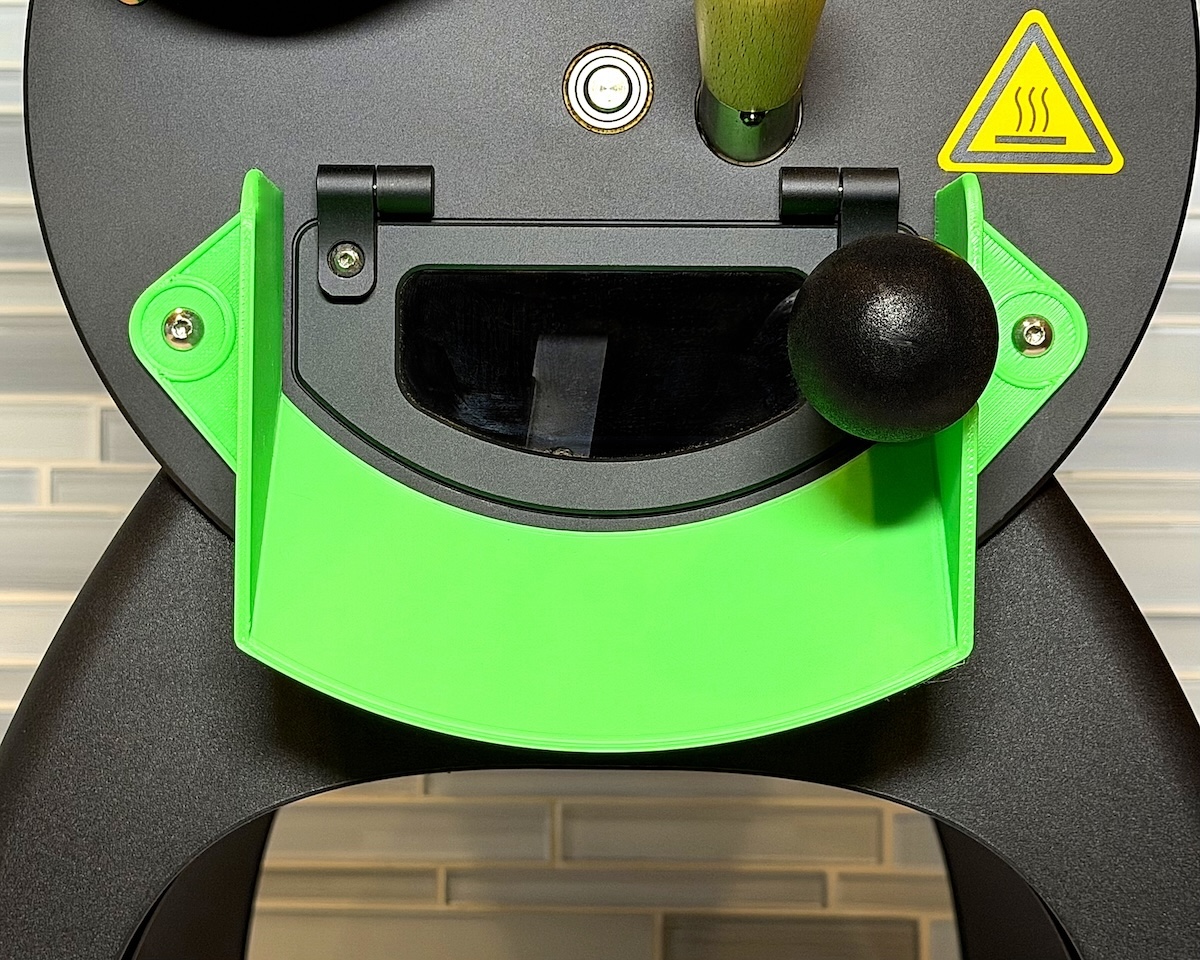

Aillio Bullet R1 Bean Deflector: Solving the Scattered Bean Problem

Precision-engineered bean deflector for Aillio Bullet R1 roasters. Made with premium Polymaker ABS for superior heat resistance and durability. Eliminates bean scatter during cooling tray dumps—professional upgrade for serious roasters.

Every Bean Counts

If you’ve dumped a roast into your Aillio Bullet R1’s cooling tray and watched beans scatter across your counter, you know the frustration. One or two beans per batch doesn’t sound like much until you calculate the total loss across the lifetime of your roaster.

I designed this bean deflector to solve that exact problem.

The Problem with Generic Deflectors

Most 3D-printed Bullet accessories use whatever filament happens to be loaded in the printer. The issue? Repeated thermal cycling, vibration, and physical stress cause inferior materials to warp, crack, or degrade within months. And don’t even think about what off-brand filament chemicals are leaking into your beans.

This deflector is different.

Engineering for the Real World

Material Selection: Polymaker PolyLite ABS

I chose Polymaker PolyLite ABS specifically for its:

- High-temperature resistance: Maintains dimensional stability in the roasting environment

- Impact strength: Handles repeated bean dumps without cracking

- Chemical resistance: Won’t degrade from cleaning or chaff exposure

- Long-term durability: Engineered-grade formulation, not generic commodity filament

Design Philosophy

- Drop-in installation: Uses two existing faceplate screws —no drilling, no permanent modifications

- Over-engineered thickness: double the thickness of competitor’s deflectors

- Dimensional accuracy: ±0.03mm tolerance ensures consistent fit across production runs

- Thermal geometry: Positioned to avoid heat zones while maintaining optimal bean guidance

Installation & Compatibility

Compatible with: Aillio Bullet R1 V2 coffee roaster

Install time: <3 minutes

Tools required: Hex screwdriver (provided with your Bullet), or any 3mm Allen wrench.

Process:

- Remove two existing faceplate screws

- Position deflector over mounting holes. It helps to put the screws through the deflector holes first.

- Reinstall screws (hand-tight—do NOT overtighten)

- Done

Customization Options

Standard colors:

- Black (matte)

- Green (satin)

Custom colors available on request (adds 1 business day to lead time)

Why I Built This

As someone who runs both a specialty coffee operation and a precision manufacturing workflow, I got tired of workarounds. The Bullet R1 is an exceptional machine but the bean scatter issue needed a proper solution, not a duct-tape fix or a cheap poorly-designed solution made of the wrong filament.

This deflector represents the intersection of my roasting experience and engineering background: a purpose-built tool that solves one problem extremely well.

Specifications

| Property | Value |

|---|---|

| Material | Polymaker PolyLite ABS |

| Print Layer Height | 0.2mm |

| Infill | 40% gyroid |

| Temperature Resistance | Continuous use to 85°C |

| Dimensional Tolerance | ±0.03mm |

| Weight | 22g |

| Finish | Matte; minor layer lines may be visible |

Next in the Pipeline

This deflector is the first in a series of Bullet R1 accessories I’m developing. Next up is a redesigned exhaust redirector.

Feedback from the roasting community drives my roadmap. If there’s a workflow pain point you’re facing, I want to hear about it.

Order Now

Available at MKK Design Craft on Etsy.

International shipping available—message for quote.

Technical Notes

Why ABS over PETG?

While PETG offers excellent layer adhesion and is easier to print, ABS provides superior:

- Long-term dimensional stability under thermal cycling

- Impact resistance (critical for bean dump forces)

- Chemical resistance to oils and cleaning agents

- Lower moisture absorption (maintains fit over time)

Why not injection molding?

At current volume projections, 3D printing offers:

- Zero tooling cost (no $5K–$15K mold investment)

- Rapid design iteration based on user feedback

- Economical small-batch production

- Customization flexibility

If demand scales to 500+ units/month, I’ll transition to injection molding for cost efficiency.

Questions? Feedback?

Drop a comment below or reach out via the Etsy shop. I read every message and incorporate user insights into product revisions.

Current roasters: What other Bullet R1 workflow improvements would you prioritize?

Designed, tested, and manufactured in-house. Small-batch production. Zero compromises.